Bending

Wilson Tool leads the industry with service, quality and innovation. With a full selection of precision and American Planed press brake tooling styles, along with clamping technology, we manufacture state-of-the-art tooling to increase your productivity and efficiency.

Need Help?

Contact aTooling Technician

Also known as Z bends or Joggles, the Offset punch and die set is able to make two bends in one machine stroke. This is the solution for applications requiring materials to be joined together or when you need to make a second bend that will not interfere with the first bend. Wilson Tool has many stock sizes in the standard catalog, but custom sizes and angles can also be made.

WT-Style Precision press brake tooling is made to run in TRUMPF*-style press brakes. Tools are easy and fast to load with a push-button mechanism that allows for front-loading. Sections are offered in lengths that can be maneuvered by a single operator. Tooling is Nitrex® heat-treat processed for longer life, minimized material marking and galling.

All sectionalized WT-Style Precision punches come with “ear pieces” for easier box bending, and return flanges. Finally, all of Wilson Tool International’s press brake tooling is laser marked for easy identification, storage and reordering.

Special WT-Style Precision tooling options from Wilson Tool are virtually endless with lead times as quick as 3 days. Explore these online options for the most common special tooling profiles or contact us for a more customized option. Your solution will be manufactured and delivered in record time.

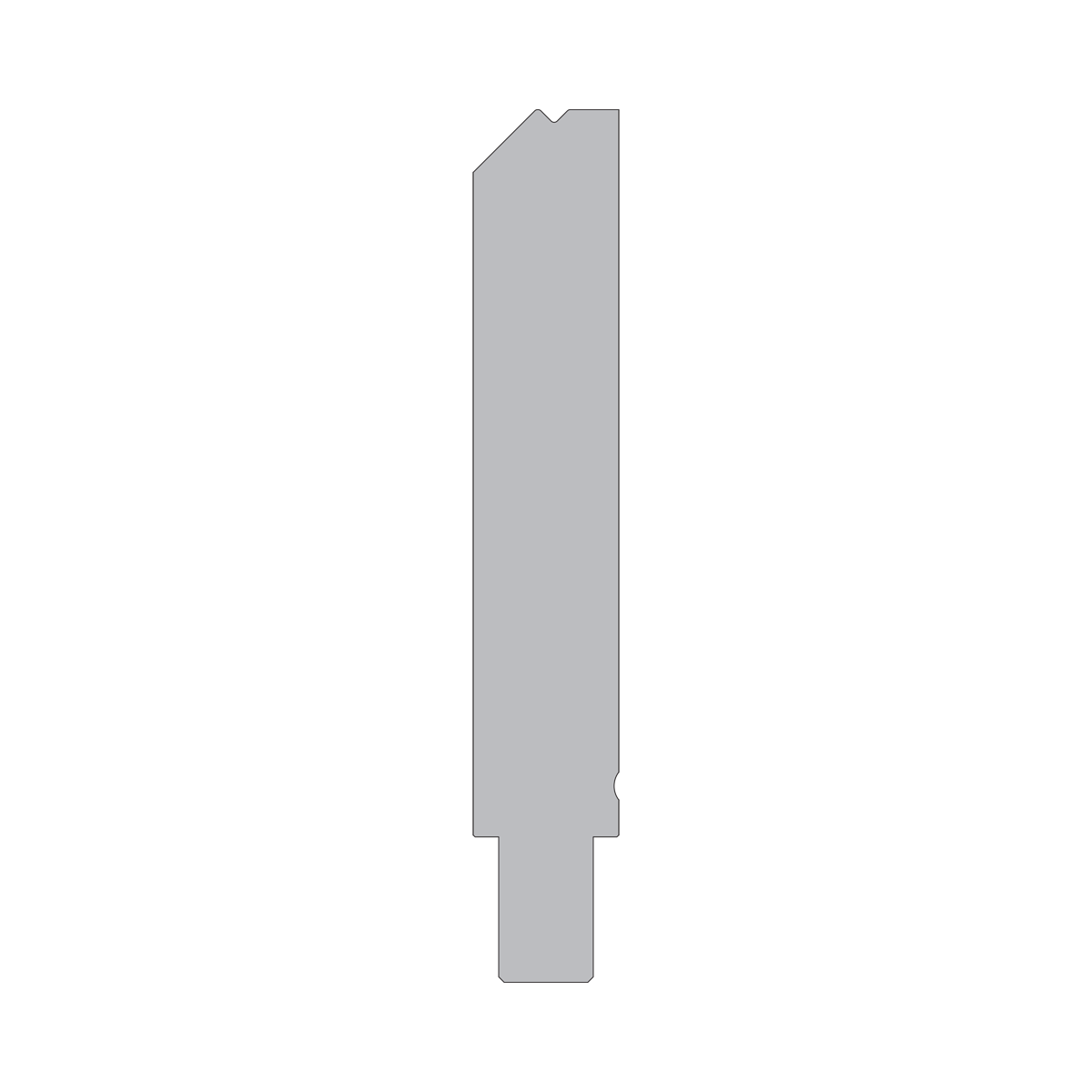

WT, Offset, Die Only, 100mm Family, 90°, 3.2mm [.125"] Offset

63190125X1LD-WT, Offset, Die Only, 100mm Family, 90°, 3.2mm [.125"] Offset, Sectionalized X1 Set 500mm [19.69"] Length Includes: (3) 100mm [3.937"], 45mm [1.772"], 40mm [1.575"], 35mm [1.378"], 30mm [1.181"], (2) 25mm [.984"]Add a File or Comment (Optional)